For frequent use

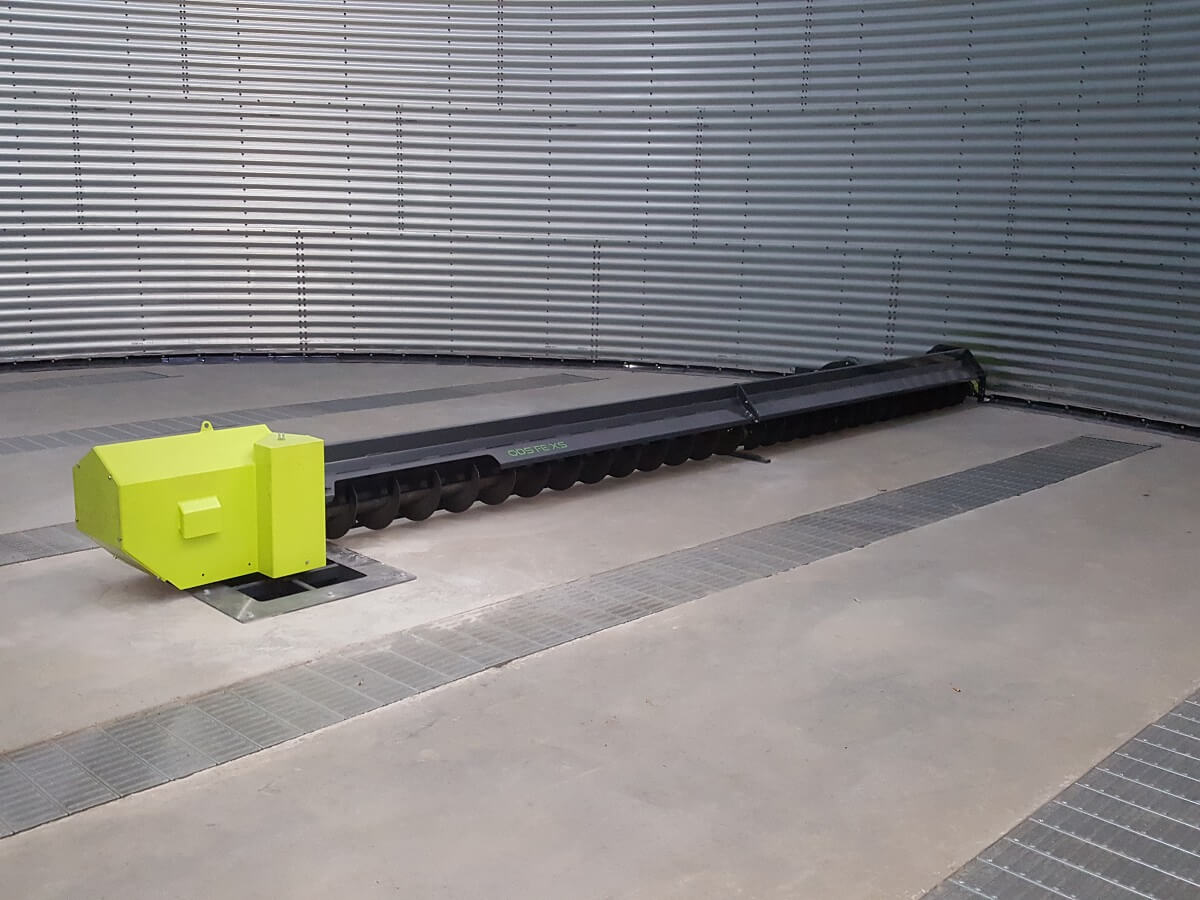

The sweepauger ODS FE XS unloads, without any human intervention, the remaining grain (wheat, corn, barley, sunflower seeds, paddy…) on the floor of flat bottom silos after the discharge by gravity.

Installation is done on flat bottom silos with concrete or metallic walls.

Silo floor can be full ventilated.

XS model is perfectly adapted for a frequent use (up to around 6-8 times a year).

Two versions are available for all kinds of materials to discharge (motor in silo or in tunnel).

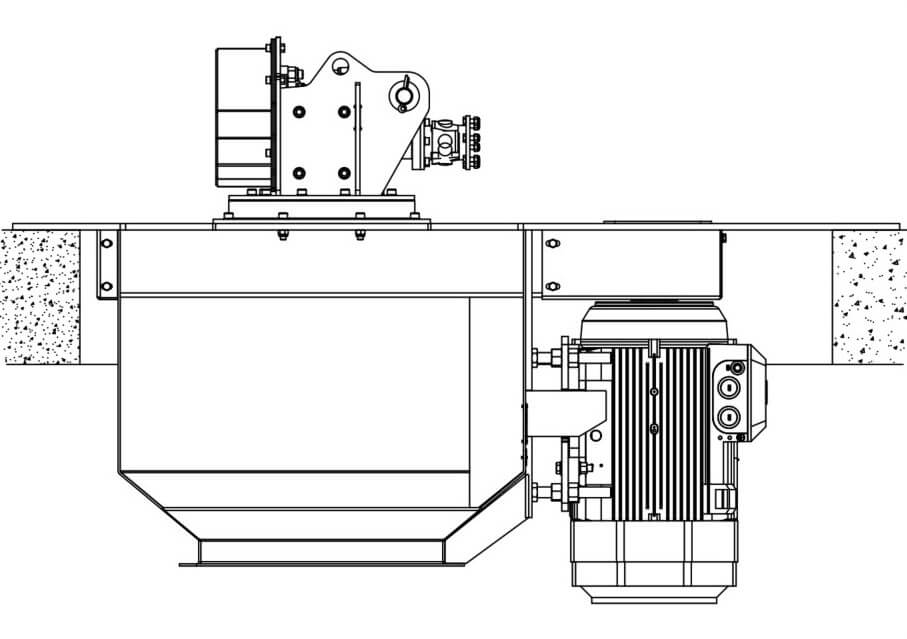

VERSION WITH GEAR MOTOR IN SILO

The screw is directly coupled to a parallel shaft gear motor.

The gear motor is assembled on a pivot and connected to an electric rotary collector for a continuous rotation of the sweepauger around the silo.

Intermediate outlets with slide gates are required for an easy start-up of the sweeping auger.

This model has a very low footprint in the tunnel.

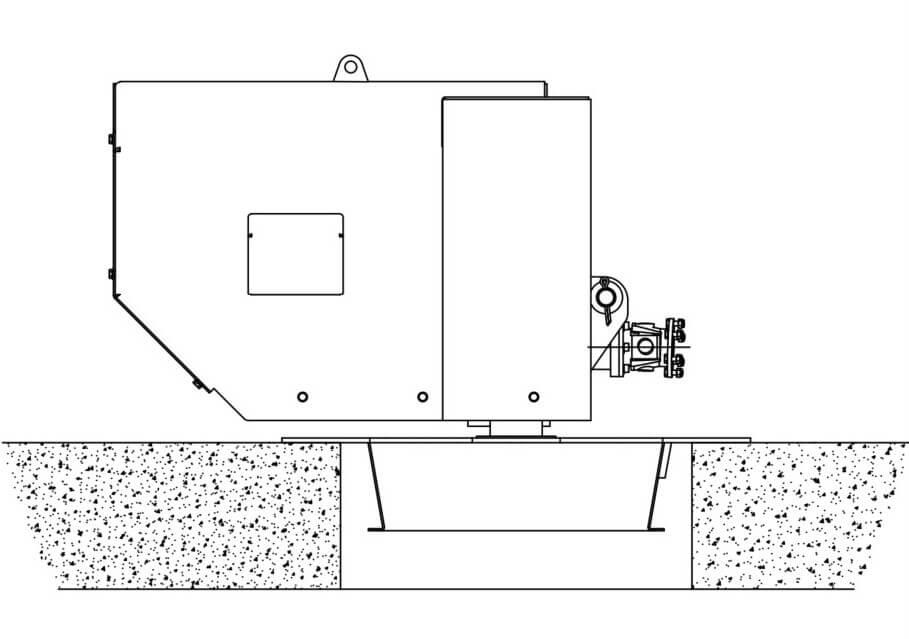

VERSION WITH MOTOR OUTSIDE SILO (INSIDE THE TUNNEL)

This version has the motor and the belt transmission located in the tunnel.

The belt transmission is connected to a gear angle in central position allowing a continuous rotation of the sweepauger.

Intermediate outlets with a slide gate are required for an easy start-up of the sweepauger after discharge by gravity.

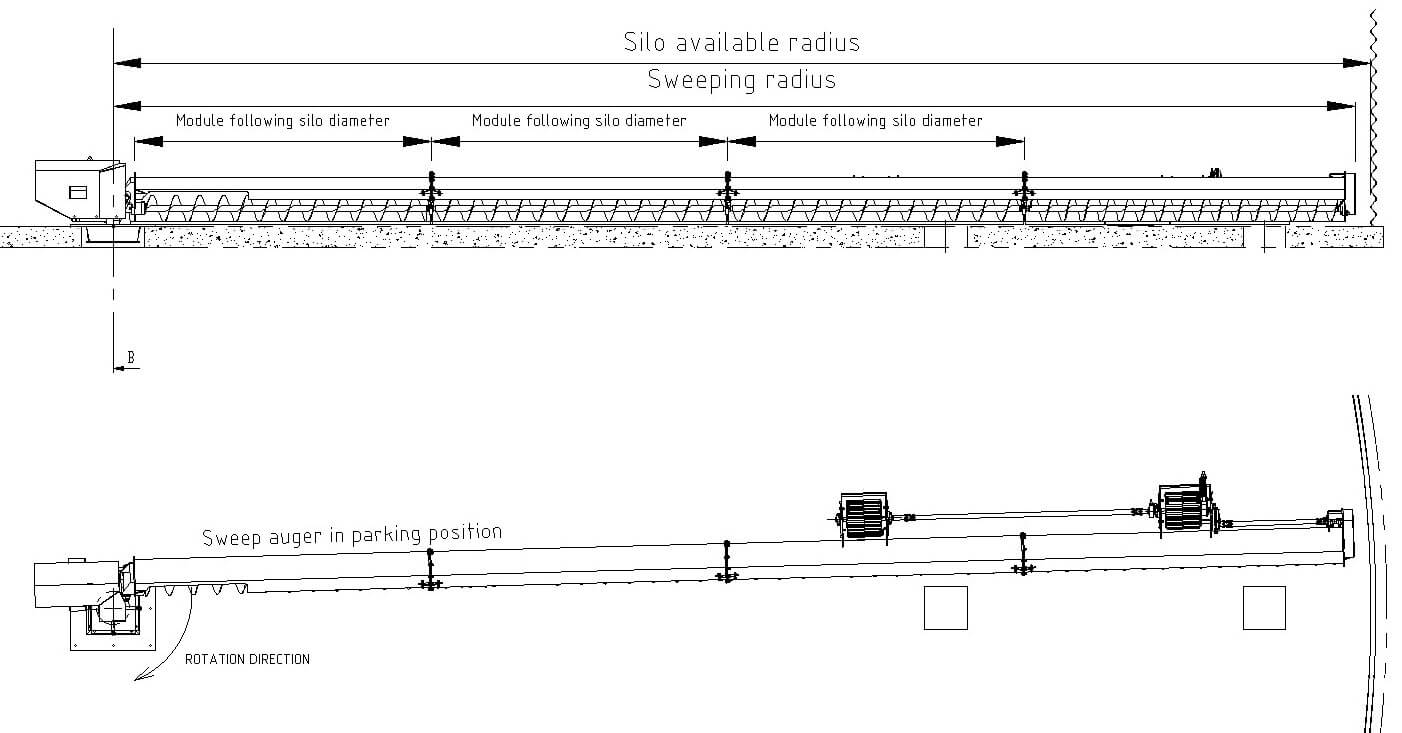

PLAN IN DRAWING ODS FE XS

MODELS AND PERFORMANCES

| Model | XS 200 | XS 245 | XS 260 |

|---|---|---|---|

| Flight Ø | Ø 200 mm | Ø 245 mm | Ø 260 mm |

| Silo Ø | Ø 6m to Ø 27m | Ø 6m to Ø 32m | Ø 6m to Ø 32m |

| Discharge capacity min. (based on Wheat d0,75) | 25 TPH | 50 TPH | 100 TPH |

| Discharge capacity max. (based on Wheat d0,75) | 50 TPH | 100 TPH | 150 TPH |

| Motor power min. | 2,2 kW | 3 kW | 5,5 kW |

| Motor power max. | 9 kW | 22 kW | 30 kW |

STANDARD

EQUIPMENT RIGIDITY

The particular rigidity of the beam, thanks to a special design and a fabrication using the most relevant materials, allows a permanent penetration of the sweepauger in the mass of materials.

HIGH PERFORMANCES TO GUARANTEE DISCHARGE RATES

All along the screw, the material is regularly absorbed, from the extremity until the central outlet. This allows an easy operation, and a quiet sweeping of the material, limiting collapses of material inside the silo. The sweepauger is permanently and softly backed on to the mass of materials, only advancing when there is room enough.

HUMAN SAFETY DISCHARGE OPERATION

The sweepauger has been elaborated with a high conscience of safety, having in mind that it doesn’t need any human presence in the silo during the operation.It is recommended to put a “safety device” at the door entrance in the silo, prohibiting to open the door when the sweepauger is operating.

ENERGY SAVINGS

The motor can be located either on the equipment itself inside the silo, or under the silo in the tunnel. The direct coupling gear motor/screw (motor in the silo) gives an optimal efficiency to the screw.

The regularity of unloading rate optimizes the unloading time and participates to energy savings.

PERFORMANT ADVANCE SYSTEM

The advance of the sweepauger is performed by one (or several) squirrel cage wheel with rubber bars.

Using a specific mechanism and appropriate adjustments, the wheel never slips on the silo floor.

The wheel has also a self cleaning design.

As a standard, a belt transmission drives the wheel rotation, which gives the guarantee of a long lasting operation.

OPTIONS

PARKING POSITION SENSOR

To receive an electric signal when the sweepauger is back in parking position. This system avoids any visual control of the parking position.

Having it along the silo wall gives an accurate position to the sweepauger when stopping in parking position.

WIPER BLADES

Located on the back of the frame. It helps cleaning the silo floor. Efficiency is even better when floor is smooth.

HOPPER LEVEL DETECTOR

Located inside the central hopper, it sends a signal to stop automatically the sweepauger if the unloading hopper is clogged with excess materials. This device protects the machine against damages.

SIDE WALL CLEANING SCREW

CONTROL PANEL

To even improve the cleaning of the accumulated material along the silo wall.

Two versions available according to the function needed (uncompaction/cleaning).

A control panel including the last technology can be proposed to drive the sweepauger.

ANTI ABRASION PACK

Developed for materials having abrasion properties. It includes special extra protection on the most sensitive parts in contact with the materials.