COMPACT SOLUTION FOR VERY HIGH GRAIN FLOWING CAPACITY WITH EXCLUSIVES BENEFITS !

The L DSM is the only sweepauger model which truly does not require the use of intermediate emptying outlets to start and therefore protects the silo from any unbalance due to accidental off-centre emptying.

The thrust power of the sweepauger and the angle of attack of the screw allows the L DSM sweeping auger to unload materials with large slope angles.

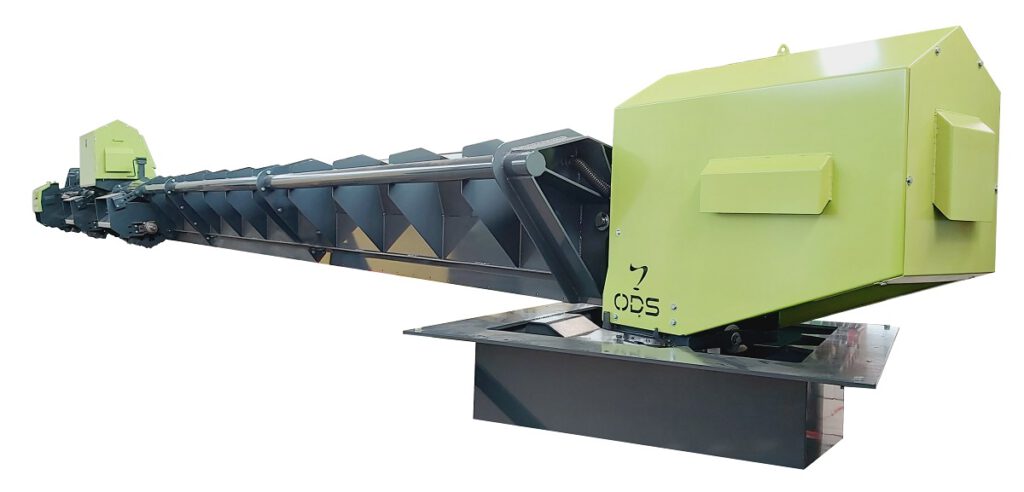

The use of two decoupled augers makes possible to install high powers on large diameter screws and to achieve very high discharge rate of 500TPH !

The 2 screws are coupled to parallel shaft geared motors located inside the silo.

A central geared motor is mounted on a ball bearing, while the second geared motor is located on the equipment frame.

Both gearmotors are connected to an electric rotary manifold for continuous rotation of the sweepauger around the silo.

The L DSM sweepauger has a small footprint in the tunnel.

The simple electromechanical design makes maintenance easier to tackle without high qualification for the customer maintenance team.

ODS provides “Zero Human Entry” heavy duty sweepaugers for port and river terminals.

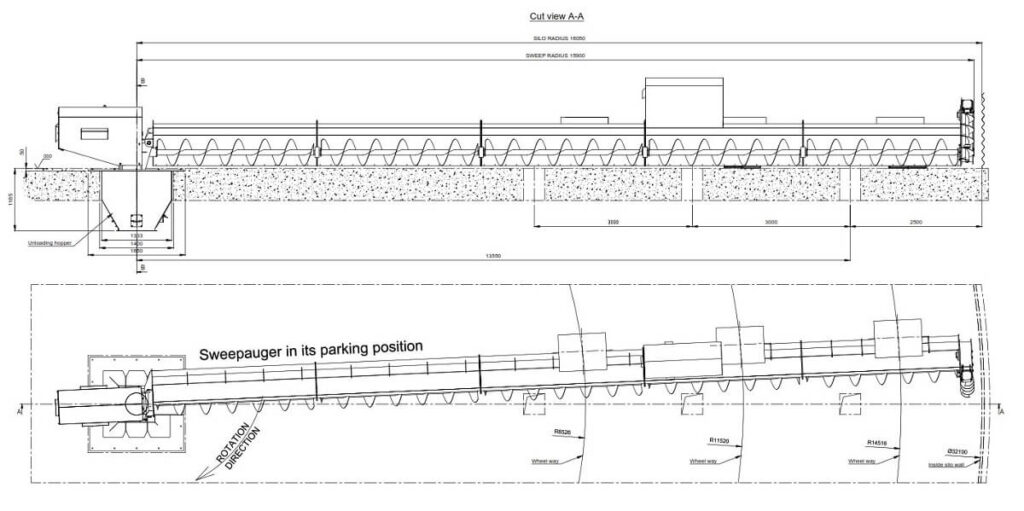

GENERAL PLAN IN DRAWING OF ODS FE L DSM

MODEL AND PERFORMANCES

| Model | L DSM 500 |

|---|---|

| Flight Ø | Ø 500 mm |

| Silo Ø | All commercial silos and wide range of domes |

| Discharge capacity according to sweeping diameter (based on Wheat d0,75) | Up to 500 TPH |

| Motor power max. | 115 kW |

STANDARD

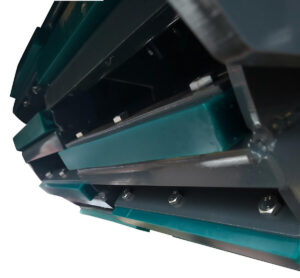

VERTICAL SIDE WALL CLEANING SCREW

To gently dislocate the accumulated compressed grain along the silo wall.

The position of the screw is studied to resist to high advance pressure given by the large pushing wheels.

REINFORCED HEAVY DUTY FRAME

To resist to the worst conditions and able to absorb high pushing efforts from the wheels or from the material flow.

ANTI ABRASION PACK

Developed for materials having abrasion properties. It includes special extra protection on the most sensitive parts in contact with the materials.

LIFTING SYSTEM FOR EASY MAINTENANCE OPERATION

It becomes very easy to lift the few tons of the L DSM using the embedded devices on the equipment.

LARGE MOTORISED WHEELS

A gear motor is installed on the wheel to give a high advance pressure to the screw and give a better speed regulation.

No tracking system required on the floor. The high grip of the pads makes the wheels able to run even inside impurities.

OPTIONS

FT “No parking position” system

L DSM starts under the grain from anywhere !

With the FT adaptation, the L DSM sweepauger is able to start right after the gravity discharge from the central outlet regardless of its starting position in the silo.

PARKING POSITION SENSOR

To receive an electric signal when the sweepauger is back in parking position. This system avoids any visual control of the parking position.

Having it along the silo wall gives an accurate position to the sweepauger when stopping in parking position.

HOPPER LEVEL DETECTOR

Located inside the central hopper, it sends a signal to stop automatically the sweepauger if the unloading hopper is clogged with excess materials. This device protects the machine against damages.

WIPER BLADES

Located on the back of the frame. It helps cleaning the silo floor. Efficiency is even better when floor is smooth.

CONTROL PANEL

A control panel including the last technology can be proposed to drive the sweepauger.